In this study effect of Thyme Thymus vulgaris ultrasonic extract on the quality of Hypophthalmichthys molitrix surimi was evaluated. However different from previous research results it is believed that the quality of heating at 90 C is the best.

Manufacturing Process Of Imitation Fish Paste Download Scientific Diagram

Product Description Aquatic Product Raw Material.

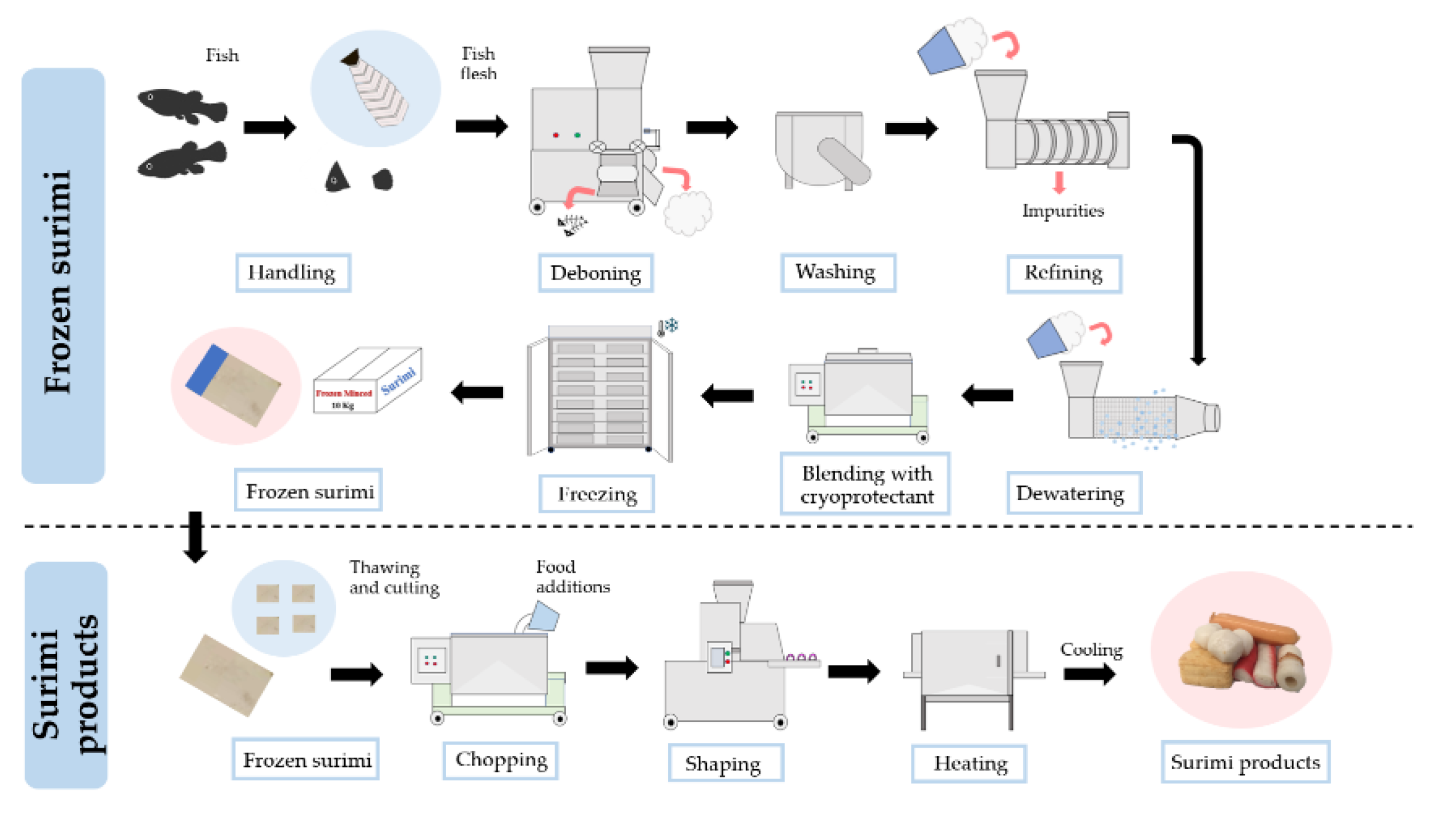

. Surimi manufacturing process 1. The product known as Frozen Surimi is minced fish flesh gone through washing with water draining the water mixing thoroughly with sugar and polyphosphate and freezing. Macterial Handling.

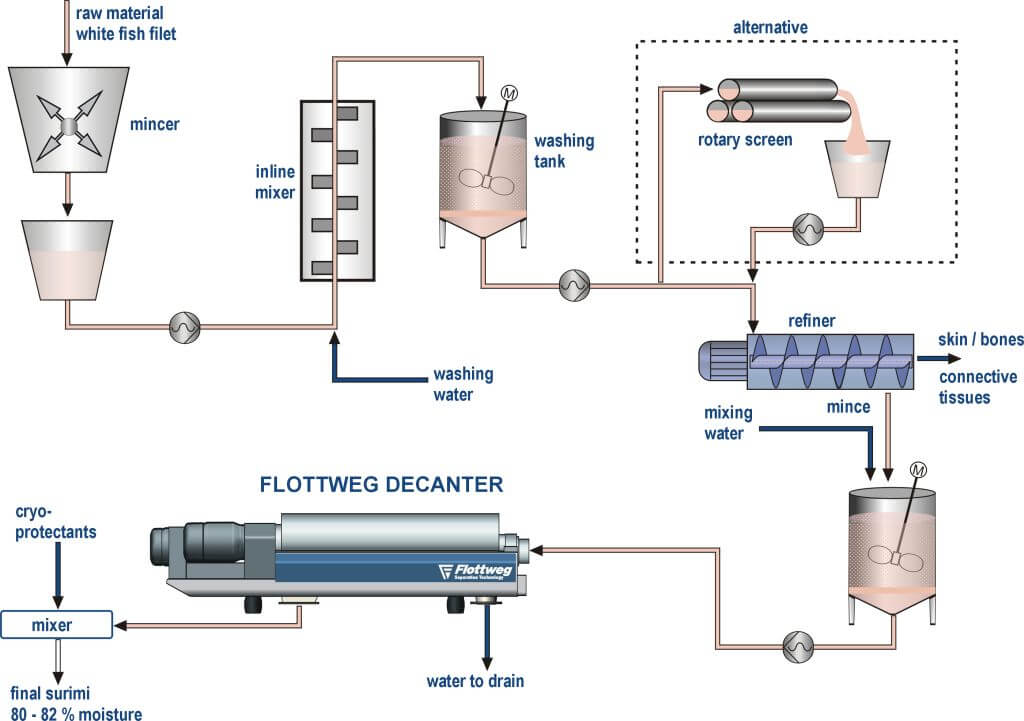

Most are normally turned into fish meals and other products used as components in animal feed. The process of claim 2. In conventional production of surimi screw presses dewater the minced fish meat.

Since the beginning of 1980 when surimi-based products were first introduced into the US market with explosive response the surimi analogue production showed an exponential growth from a mere 2760 metric tons mt in 1983 to 80 000 mt in 1990 while the surimi production from Alaska pollock has risen from 58 200 mt in 1988 to a current level of 163 200 mt Freese 1992. Surimi processing technology involves the washing of minced fish in order to purify and concentrate the muscle proteins which may be then further processed into secondary products or stabilized by the addition of cryoprotectants frozen and stored for later use. This step crushes the mince to a flat shape with a crushing device.

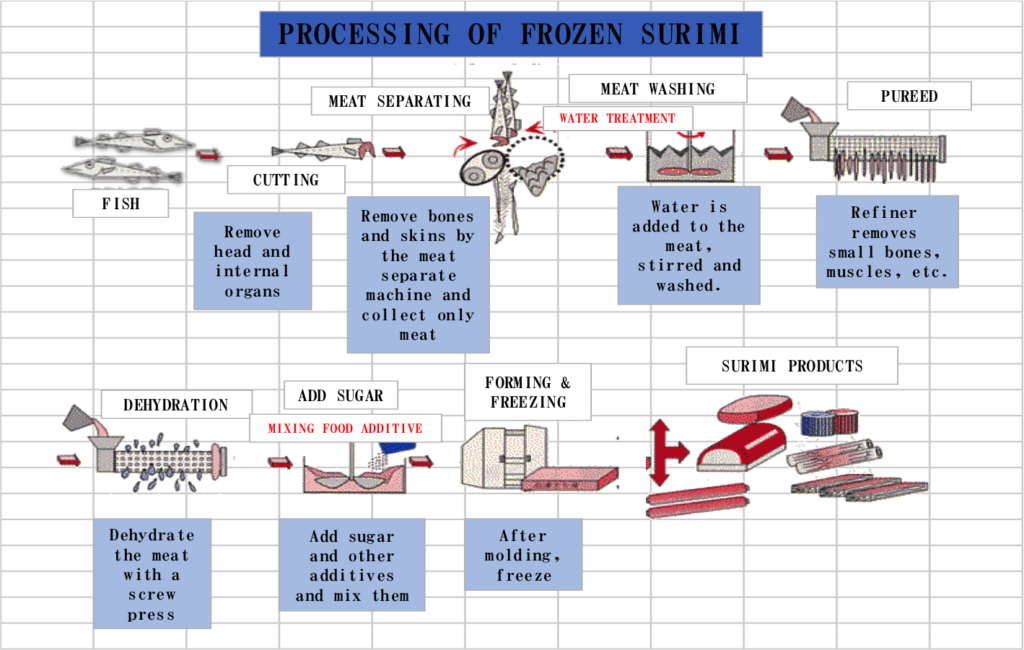

Normally a rotating screen provides superficial cleaning of the wash water. Daily Metal Detector Record 1. Surimi is Japanese term commonly used for minced fish flesh obtained after necessary processing steps.

HACCP Plan Form 6. This entry was posted in News Projects. Surimi processing Fish processing operations result in many leftovers that are traditionally considered relatively low in value.

Pollock Theragra chalcogramma Raw material harvest Area. The muscle is then minced by passing the material through a perforated screen and collecting the mince. Surimi processing on limited space Adding surimi processing to the onboard factories is trending in the fishing industry.

Study to Improve Adding Additives and W ashing Step on Surimi Processing from Moontail Bigeye process of Hoa Thang Company as follows. Gadre Marine ensures 100 quality for the entire surimi producing process. The kidney intestines parts of stomach and liver if allowed to remain may severely damage the quality of protein during processing.

Impurities such as blood and fat are removed in this process. Heading and gutting. The result is that the mince becomes flatter and has increased surface area for a given volume of.

Surimi manufacture is a multi-step process as shown in Fig. The head viscera and most of the backbone of the fish are removed. All machinery for surimi processing on this video- screw conveyor- rotary fish washing machine- Cut fish washer with eye link belt- Meat separator- Mixing t.

Pacific whiting Merluccius spp. For this purpose the leaves of Thymus. A process for the production of a surimi which comprises distinguishing fish highly contaminated with sporozoans from less contaminated ones on the.

Preparation of Surimi Beheaded eviscerated and skinned Washing with cleaned chilled water Filleting by knife Deboning Mincing Washing Fish 01Nacl solution for 5- 8min 6. Frozen surimi is mainly. When rinsing pike surimi rinsing with a CaCl2 solution can improve the gel properties of the surimi.

Followed by dry surimi powder from Sutchi Catfish Pangasianodon hypophthalmus. The process of claim 1 wherein the crushing step is accomplished by a mince crushing device including a mincer drum. Better recovery - better profit opportunities process a wide range of different fish species.

1984 Document available for consultation in the library of the IIR headquarters only. From raw fish going through many stages well get the final product which is packed surimi blocks ready for export. 2 3 Under most circumstances surimi is processed immediately into a formed and cured product.

Gadres mission is to continuously explore new technologies for better quality Surimi. Bookmark the permalink. The manufacture of surimi involves washing a minced fish filet in a two or three-stage process.

Process Collection - Rotary drum static garbage collector - Equalization 1 - Equalization 2 - Super shallow flotation device - Storage - Anaerobic reverse filtration - Aerobic - Sedimentation - Disinfection. Surimi Processing Line Posted on December 1 2021 by MB339544 01 Dec This is a surimi production line being applied at one of our factories in Quang Tri. Mechanical separation of fish meat The fish meat separation process can be done either manually or mechanically and is an important processing step that determines the quality of the surimi.

Effective processing of surimi is an intricate process with multiple steps from fresh fish to processed cleaned washed drained and frozen in surimi blocks. Rinsed 3 times with 4 times water to obtain the best gel quality. Surimi Generic HACCP Plan 1.

The basic steps of production of surimi are as follows. Fish heads are removed guts are cleaned and bones are removed with large amounts of water to separate the waste material from the muscle tissue. Industrial Tools Food Processing Machine How its made surimi hepl you understand surimi.

120 Ngu yen Thi Le Phuong et al. A process to produce higher grade surimi from the flesh of fish using less fresh water comprising. Pressing Final pressing by screw-press to adjust water level at 75-78 Screening to separate skin bone if exist in washed and sieved minced Frozen storage at -250 C temp.

Hazard Analysis Worksheet 5. In the preparation process of carp surimi gel Li Haiping et al.

Appendix Vi Proposed Draft Code Of Practice For Fish And Fishery Products

Foods Free Full Text Asian Carp An Alternative Material For Surimi Production Progress And Future Html

Scielo Brasil Effect Of Gelatin Based Edible Coatings On Quality Of Surimi From Pearl Mullet I Alburnus Tarichi I Guldenstadt 1814 During Cold Storage Effect Of Gelatin Based Edible Coatings On Quality Of

Flow Diagram Of Surimi Processing Download Scientific Diagram

Manufacturing Process Of Imitation Crab Stick Download Scientific Diagram

Manufacturing Surimi With Decanter Flottweg Separation

Flowchart Of The Surimi Processing Steps Download Scientific Diagram

Surimi An Overview Sciencedirect Topics

Surimi Processing Centrifuge Decanter Equipment For Surimi Production Zk Separation

Surimi Crab Stick Processing Line Youtube

Surimi An Overview Sciencedirect Topics

The Basic Of Frozen Surimi How To Make Delicious Kamaboko

Flowchart Of The Surimi Processing Steps Download Scientific Diagram

Do You Know Trip To Ipm Review

How It S Made Surimi Surimi Processing Line Youtube

Appendix Vi Proposed Draft Code Of Practice For Fish And Fishery Products